Common faults and solutions for gear reducers

Release Time:

2017-08-16

Overview

[Wangguan Hardware and Electrical Network] Gear reducers are generally used in low-speed, high-torque transmission equipment. Ordinary reducers also use several pairs of gears with the same principle to achieve the ideal reduction effect. The ratio of the number of teeth of the large and small gears is the transmission ratio. With the continuous development of the reducer industry, more and more enterprises are using reducers.

Below is an introduction to common malfunctions and troubleshooting methods during gear reducer operation:

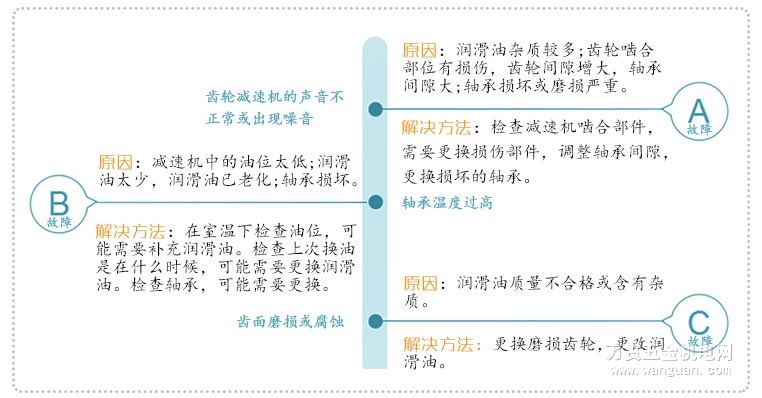

Common Malfunctions A, B, C and Troubleshooting Methods in Gear Reducer Operation

A、Abnormal Sounds or Noise from the Gear Reducer

Cause: Too many impurities in the lubricating oil; damage to the gear meshing parts, increased gear clearance, large bearing clearance; severe bearing damage or wear.

Solution: Inspect the meshing components of the reducer, replace damaged parts as needed, adjust bearing clearance, and replace damaged bearings.

B、Excessive Bearing Temperature

Cause: Oil level in the reducer is too low; insufficient lubricating oil, lubricating oil has aged; bearing damage.

Solution: Check the oil level at room temperature, and lubricating oil may need to be added. Check when the last oil change was; lubricating oil may need to be changed. Inspect the bearing; replacement may be needed.

C、Gear Surface Wear or Corrosion

Cause: Poor quality lubricating oil or presence of impurities.

Solution: Replace worn gears and change the lubricating oil.

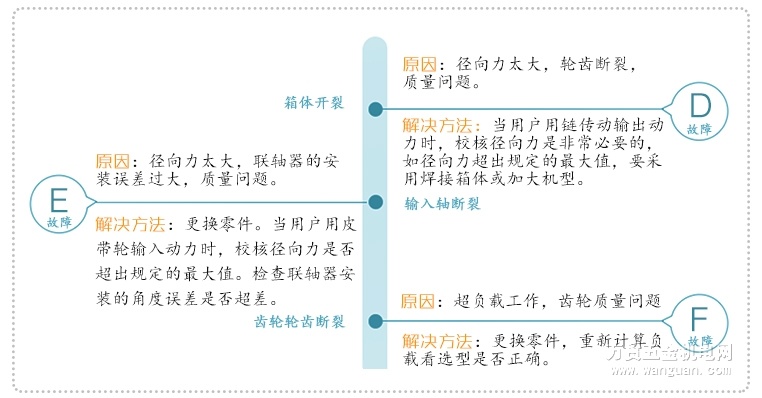

Common Malfunctions D, E, F and Troubleshooting Methods in Gear Reducer Operation

D、Housing Cracking

Cause: Excessive radial force, broken gear teeth, quality issues.

Solution: When the user uses chain transmission to output power, it is very necessary to check the radial force. If the radial force exceeds the specified maximum value, the housing should be welded or a larger model should be used.

E、Input Shaft Fracture

Cause: Excessive radial force, large installation error of the coupling, quality issues.

Solution: Replace parts. When the user uses a pulley to input power, check whether the radial force exceeds the specified maximum value. Check if the angular error of the coupling installation exceeds the limit.

F、Gear Tooth Fracture

Cause: Overload operation, gear quality issues.

Solution: Replace parts, recalculate the load to see if the selection is correct.

More News

Introduction to imported gear oil pumps

2017-08-16